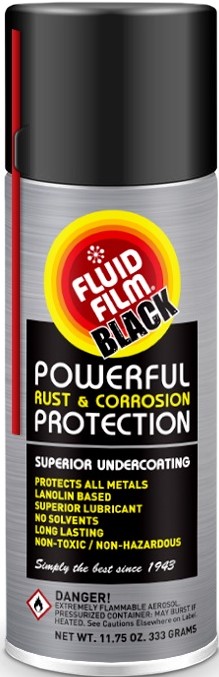

When it comes to protecting your valuable equipment and surfaces from rust and corrosion, Fluid Film stands as a trusted brand. However, the decision between Fluid Film Black and Fluid Film Red can leave you pondering which one is truly the best.

So, Fluid Film Black vs Red: Which One is the Best?

Fluid Film Black is preferred over Fluid Film Red due to its visually appealing black color, which hides imperfections and adds a professional look. It also offers a thicker and waxier texture, providing better coverage and resistance to wash-off. Both variants offer equally powerful corrosion protection and lubrication capabilities.

Keep on reading to find out more!

Fluid Film Black vs Red [Quick Comparison]

Explore the differences in color, appearance, texture, and functionality to determine which one suits your needs better.

| Features | Fluid Film Black | Fluid Film Red |

|  | |

| Color | Black Coating | Clear or Tan Color |

| Appearance | More Appealing Black Color | Light Red Less Popular Among Customers |

| Texture | Thicker And Waxier Feel | Regular Texture |

| Functionality | Powerful Corrosion Protection | Powerful Corrosion Protection |

| Price | CHECK PRICE | CHECK PRICE |

Color

Fluid Film Black, with its deep black coating, offers a superior aesthetic appeal compared to Fluid Film Red, which has a clear and tan color. Fluid Film Black is the ideal choice for those who desire a visually striking and professional look, thanks to its bold black color.

Additionally, it is worth considering whether a clear coat will effectively conceal tiger stripes.

It effectively hides surface imperfections, creating a cleaner and more polished finish. In contrast, Fluid Film Red’s clear and tan color may be considered less visually appealing, as it lacks the boldness and visual impact of the black variant.

The clear and tan color of Fluid Film Red can be crucial for industrial applications. But overall, there’s no denying the fact that Fluid Film Black is more vibrant.

Summary: If you prefer clear color, then Fluid Film Red is the way to go. However, if you want to add a professional look to your car, then Fluid Film Black is the only option!

Appearance:

Fluid Film Black, with its more appealing black color, is generally considered better in terms of appearance compared to Fluid Film Red. The red one has a light red color that is less popular among customers.

The deep black color of Fluid Film Black gives it a sleek and professional appearance, making it visually striking and highly sought after by users. It adds a touch of sophistication and can effectively enhance the overall aesthetics of the treated surfaces. And you can really see the difference in appearance easily.

On the other hand, Fluid Film Red’s light red color may not be as visually appealing to customers, leading to its lower popularity. While personal preferences may vary, the majority of users tend to prefer the bold and captivating black color of Fluid Film Black when it comes to the overall appearance of the product.

Summary: For a sleek and sophisticated look, go with Fluid Film Black. If you prefer just a simple, clear appearance, then choose the Red one.

Texture:

When comparing Fluid Film Black and Red, the thicker and waxier texture of Fluid Film Black outperforms the regular texture of Fluid Film Red. This quality enables Fluid Film Black to adhere better to surfaces, offering superior coverage and long-lasting protection against corrosion.

With such textures, washing the car anywhere, including in the driveways, is no big deal!

It also makes it more resistant to wash-off, which is beneficial in applications where exposure to water is a concern. The waxier texture adds a layer of durability and protection. On the other hand, Fluid Film Red has a regular texture that is similar to other standard lubricants and coatings.

While it spreads easily and penetrates well into tight spaces, it may not offer the same level of thickness and waxiness as Fluid Film Black. Therefore, in terms of texture, Fluid Film Black is generally considered the better option for those seeking enhanced protection and adherence.

Summary: In terms of offering better texture, Fluid Film Black performs better than the Red iteration.

Functionality:

Both Fluid Film Black and Fluid Film Red offer equally effective corrosion protection, making it challenging to determine which one is superior in terms of functionality. They both form a protective barrier that prevents moisture and air from reaching the metal surface, effectively reducing the risk of rust and corrosion.

Both Fluid Film Black and Fluid Film Red penetrate deeply, provide long-lasting protection, and offer lubrication. However, Luxacare is not recommended for car use as it focuses on appearance rather than corrosion protection.

When deciding between Fluid Film Black and Fluid Film Red, personal preference and specific application requirements play a crucial role. While Fluid Film Black may have a thicker and waxier texture, enhancing its durability in certain scenarios, Fluid Film Red’s regular texture is still highly effective in providing corrosion protection.

Therefore, the choice of which variant to use should be based on individual needs and preferences, as both offer equally powerful corrosion protection and lubrication capabilities.

Summary: Both offer the same type of functionalities for overall corrosion protection.

Final Verdict

Fluid Film Black is generally considered the better option due to its superior color, appearance, and texture. Its bold black coating provides a visually striking and professional look, effectively hiding surface imperfections.

The thicker and waxier texture of Fluid Film Black allows for better coverage, longer-lasting protection against corrosion, and improved resistance to wash-off. While both variants offer equally powerful corrosion protection and lubrication capabilities, Fluid Film Black stands out as the preferred choice for those seeking enhanced aesthetics and durability.

Tips & Tricks on Perfect Fluid Film Application

Proper application of Fluid Film is essential to ensure optimal performance and protection against corrosion. Here are some tips and tricks to help you achieve the best results when applying Fluid Film, regardless of whether you choose the black or red variant:

Frequently Asked Questions (FAQs):

Are Fluid Film Black and Fluid Film Red resistant to high temperatures?

Fluid Film Black and Fluid Film Red can withstand moderate temperatures but may degrade at extremely high temperatures. It is best to avoid prolonged exposure to extreme heat.

Can Fluid Film Black or Fluid Film Red be used on electrical components?

Fluid Film is not recommended for use on electrical components or areas where electrical conductivity is required. It is best to avoid applying it to electrical connections or sensitive electronic parts.

How often should I reapply Fluid Film Black or Fluid Film Red?

The frequency of reapplication depends on the specific conditions and level of exposure to moisture or corrosive elements. It is recommended to monitor the treated surfaces and reapply as needed when signs of wear or degradation are observed.

Bottomline

Fluid Film Black emerges as the superior choice due to its appealing black color, sleek appearance, thicker and waxier texture, and equally powerful corrosion protection. While Fluid Film Red offers reliable functionality, Fluid Film Black offers enhanced aesthetics and durability, making it the preferred option for those seeking optimal performance and visual impact.

Hopefully, we have served you well with the right insights, time to leave, bye for now!

As an Amazon Associate I earn from qualifying purchases.